What kind of reaction can produce heat four times hotter than the sun, creating some of the hottest known temperatures to occur on Earth? Arc flash may be a term you’ve never heard.

Arc flash is used to explain what can happen in a worst-case scenario when working on electrical equipment. It’s a very dangerous aspect of electricity, as it releases a tremendous amount of energy.

What is arc flash?

Arc flash is a dangerous condition associated with the release of energy caused by an electric arc. An electric arc is when electricity travels through the air instead of through a wire resulting in an arc flash. The arc flash can occur when energized electrical conductors or circuit parts are exposed, leaving them vulnerable. It can also occur within the equipment in an enclosed condition when a person is interacting with the equipment.

When electricity travels through the air, a path it should not be on, energy is released from it, giving off heat, light, sound and pressure. This essentially, creates a big electric explosion. Within seconds the energy builds exponentially and explodes. The heat is hotter than the sun, the light could burn eyes, the sound could melt typical foam ear protection and the force yields thousands of pounds of pressure, along with flying debris that could be thrown due to the arc flash.

How does it happen?

These scenarios are serious, especially if they occur in places with high-voltage electrical equipment, such as industrial and manufacturing facilities. Instantaneously, the electricity is passed from a phase to ground or phase to phase fault. This means that the electricity goes where it should not go, a live current moves through the air instead of through the intended wire or path. The electricity is taken off of its normal and safe route.

This failure can be caused by poor maintenance, moisture, dust, debris as well as failure to follow proper procedures or dropping tools on the equipment while the system is being worked on. The arc flash will last until the overcurrent protectant devices open the circuit to cut off the electricity. In other words, the electricity will continue to flow until the emergency cutoff kicks in to stop it.

How to stay safe

Warning labels

Arc flash warnings and assessments are required by OSHA (The Occupational Safety and Health Administration), the government agency that regulates workplace safety. The assessment, which must be renewed every five years, is an opportunity to test the equipment and find the potential magnitude of an arc flash also known as the incident energy.

GMC’s electrical engineering department uses a specialized software called SKM Systems Analysis to calculate potential arc flash and incident energy. On the SKM software, models are drawn and electrical data is input to simulate and calculate the level of incident energy as well as the arc flash protection needed. The data from the assessment is then used to properly label the equipment for the safety of anyone who may work on the system.

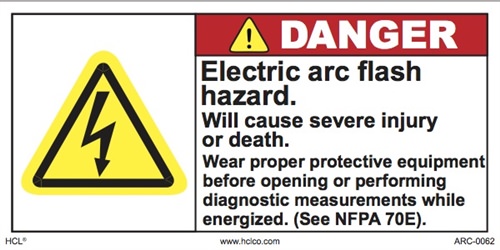

These labels on the equipment are intended to inform workers of critical information, including the proper personal protective equipment (PPE) to wear, the incident energy, the boundaries to keep while working on the equipment and the date of the arc flash assessment. It is essential that only qualified personnel work on the equipment, trained to read the labels. These individuals can gain a better understanding of the dangers of an arc flash by studying the warning labels before beginning any work on the equipment.

Incident energy rating

On top of producing warning labels, arc flash assessments also help determine the rating of the incident energy. This rating ranges from one to four, one being less dangerous and four being very dangerous. Anything from level three to four is very dangerous for an arc flash to occur, and a full PPE suit is absolutely necessary. If a facility tests over 40 calories per square centimeter, electricians are not supposed to work on the equipment unless it is completely powered off to avoid an arc flash.

Mitigation measures

Overall, the reports are generated to identify hazards and ensure safety. GMC can use these assessments to work with clients to coordinate and mitigate hazards, help minimize risks and even decrease the level of incident energy through mitigation. For example, an old facility with signs of deteriorating equipment that is not up to code would be cause for concern. This could have some potential dangers of an arc flash incident if not carefully worked on.

Some mitigation options would be to provide an overall safer install to meet NEC (National Electrical Code) as well as provide an overcurrent device like a breaker or fuse to better control the energy to serve that equipment. This mitigation would overall lower the incident energy at that point in the system, lowering the chance of arc flash.

These methods can create a safer environment that requires employees to wear less PPE, which is often expensive and cumbersome. Through GMC’s electrical engineering expertise, facilities can enhance safety for their teams, and improve efficiency by providing mitigation services while avoiding unnecessary power loss and injuries or even death.

While arc flash is rare, the threat must be treated seriously. The main objective of an arc flash assessment is to keep others safe and decrease the number of injuries and deaths per year with mitigation. Through assessments, mitigation and adhering to proper safety standards, the risk of danger can be significantly reduced while working on electrical systems.

Contact John Averrett or Jonathan Ziegler to learn more GMC’s electrical department and our arc flash mitigation services.